The Complete Fleet Vehicle Maintenance Checklist: A Comprehensive Guide

Embark on a journey through the intricacies of fleet vehicle maintenance with this detailed guide. Learn how to ensure your fleet vehicles are always in top condition and ready for the road ahead.

Explore the key components of a comprehensive maintenance checklist and discover the importance of regular upkeep for optimal performance.

Introduction to Fleet Vehicle Maintenance

Fleet vehicle maintenance refers to the regular upkeep and servicing of a group of vehicles owned or operated by a company or organization. This includes preventive maintenance, repairs, and inspections to ensure the vehicles are safe, reliable, and efficient.

Having a comprehensive maintenance checklist for fleet vehicles is crucial to ensure that all vehicles are properly maintained and in optimal condition. This checklist Artikels the specific tasks and schedules for maintenance, helping fleet managers and technicians stay organized and proactive in addressing vehicle maintenance needs.

Importance of Regular Maintenance for Fleet Vehicles

Regular maintenance for fleet vehicles is essential for several reasons:

- Ensures Safety: Regular maintenance helps identify and address potential safety issues, reducing the risk of accidents and injuries.

- Improves Reliability: By conducting regular maintenance, fleet vehicles are less likely to experience breakdowns or unexpected issues, improving overall reliability.

- Extends Vehicle Lifespan: Proper maintenance helps extend the lifespan of fleet vehicles, maximizing the return on investment for the company.

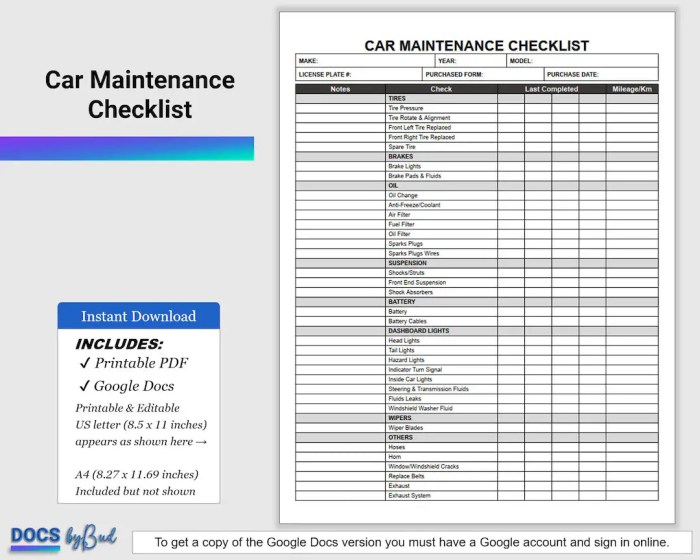

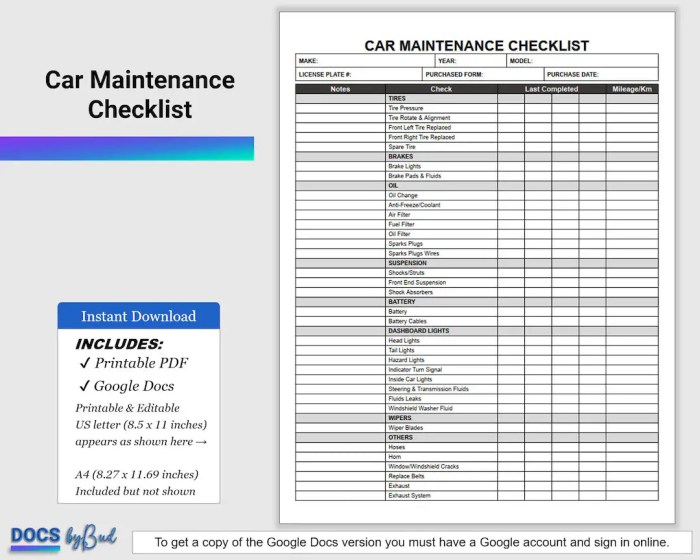

Creating a Comprehensive Fleet Vehicle Maintenance Checklist

Creating a comprehensive fleet vehicle maintenance checklist is essential to ensure the smooth operation and longevity of your fleet. By including all the necessary components in the checklist and following a regular maintenance schedule, you can prevent costly breakdowns and extend the lifespan of your vehicles.

Essential Components to Include in the Maintenance Checklist

- Oil and filter changes: Regular oil and filter changes are crucial to keep the engine running smoothly.

- Tire inspection and rotation: Check tire pressure, tread depth, and rotate tires regularly to ensure even wear.

- Brake system maintenance: Inspect brake pads, rotors, and brake fluid levels to ensure optimal braking performance.

- Fluid checks: Regularly check and top up fluids such as coolant, transmission fluid, and windshield washer fluid.

- Battery inspection: Check the battery condition, terminals, and cables for any signs of corrosion or damage.

Frequency of Maintenance Tasks for Fleet Vehicles

It is important to establish a regular maintenance schedule for fleet vehicles to keep them in optimal condition. The frequency of maintenance tasks may vary depending on factors such as mileage, driving conditions, and vehicle age. However, a general guideline for maintenance intervals includes:

- Oil and filter changes: Every 5,000 to 7,500 miles or as recommended by the manufacturer.

- Tire inspection and rotation: Every 6,000 to 8,000 miles or every six months.

- Brake system maintenance: Inspect every 12,000 to 15,000 miles or as needed.

- Fluid checks: Check fluids every 3,000 to 5,000 miles or at every oil change.

- Battery inspection: Inspect the battery every six months or as recommended by the manufacturer.

Tailoring the Checklist Based on the Type of Fleet Vehicles

When creating a maintenance checklist for fleet vehicles, it is important to consider the specific needs of different vehicle types, such as trucks, vans, or cars. Tailoring the checklist based on the type of fleet vehicles can help ensure that each vehicle receives the appropriate maintenance to perform optimally.

Some factors to consider when tailoring the checklist include:

- Heavy-duty vehicles like trucks may require more frequent inspections of brakes and suspension components.

- Vans used for frequent stop-and-go deliveries may need more frequent oil changes and brake checks.

- Cars used for long-distance commuting may require more frequent tire rotations and fluid checks.

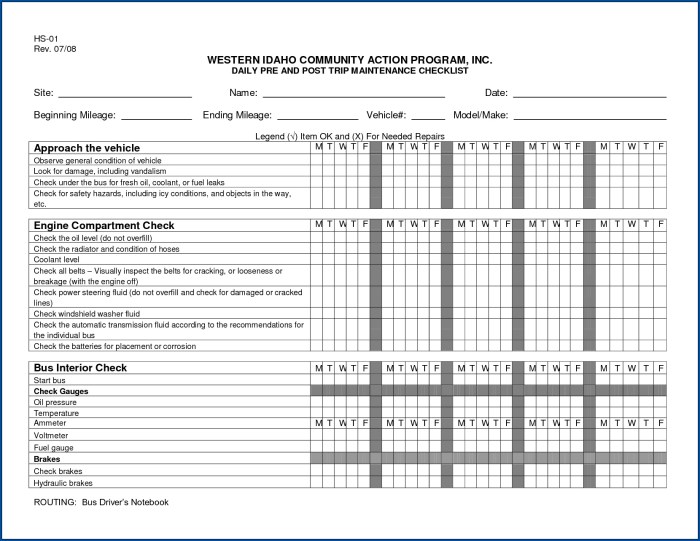

Routine Inspection Procedures

Routine inspections are crucial to maintaining the efficiency and safety of fleet vehicles. By regularly checking engine components, brakes, tires, and fluid levels, you can prevent major issues and ensure your vehicles are in top condition. Below are the detailed steps for conducting routine inspections:

Engine Components Inspection

- Inspect the engine oil level and condition, ensuring it is at the recommended level and free from contaminants.

- Check the air filter for any dirt or debris that may affect engine performance.

- Inspect the battery for signs of corrosion and ensure it is securely mounted.

- Check the radiator coolant level and top up if necessary to prevent overheating.

- Inspect the drive belts for wear and tear, replacing them if necessary to avoid breakdowns.

Brakes and Tires Inspection

- Check the brake pads and discs for wear, ensuring they are within the recommended thickness.

- Inspect the brake fluid level and top up if needed to maintain optimal braking performance.

- Check the tire pressure and tread depth, ensuring they meet the manufacturer's specifications for safe driving.

- Inspect the tires for any signs of damage, such as cuts or bulges, that may compromise road safety.

Fluid Levels Inspection

- Check the engine coolant level to prevent overheating and ensure proper engine function.

- Inspect the transmission fluid level and condition for smooth gear shifting and transmission performance.

- Check the power steering fluid level to maintain steering responsiveness and prevent steering issues.

- Inspect the windshield washer fluid level for clear visibility during driving in various weather conditions.

Scheduled Maintenance Tasks

Regular maintenance is crucial for keeping fleet vehicles running smoothly and efficiently. Here are some key scheduled maintenance tasks that should not be overlooked.

Oil Changes and Filter Replacements

Regular oil changes are essential for the health of a vehicle's engine. It is recommended to change the oil every 5,000 to 7,500 miles, depending on the vehicle and the type of oil used. Additionally, make sure to replace the oil filter at the same time to ensure proper filtration and engine protection.

Spark Plug Inspection and Replacement

Spark plugs play a vital role in the ignition process of an engine. Over time, spark plugs can become fouled or worn out, leading to poor engine performance and decreased fuel efficiency. It is recommended to check and replace spark plugs every 30,000 miles or as per the manufacturer's guidelines to maintain optimal engine performance.

Battery Maintenance

The battery is the heart of a vehicle's electrical system, providing the power needed to start the engine and run various electrical components. Regular battery maintenance, including cleaning the terminals, checking the electrolyte levels, and ensuring proper connections, is essential to prevent unexpected breakdowns.

It is recommended to inspect and service the battery every 12 months or as needed based on vehicle usage and climate conditions.

Record-Keeping and Documentation

Maintaining detailed records for each vehicle is crucial for ensuring the efficiency and longevity of your fleet. Proper documentation allows you to track the maintenance history, identify trends, and make informed decisions regarding repairs and replacements.

Importance of Detailed Records

- Record-keeping helps in tracking maintenance schedules and costs, ensuring timely servicing and budget management.

- It provides valuable insights into the overall health of the vehicles, allowing you to address potential issues before they escalate.

- Accurate records are essential for compliance with regulations and audits, reducing the risk of fines or penalties.

Benefits of Digital Tools

- Digital tools streamline the documentation process, making it easier to input, store, and retrieve data efficiently.

- Cloud-based systems offer real-time access to maintenance records from anywhere, enabling better coordination and collaboration among team members.

- Automated reminders and notifications help in scheduling maintenance tasks, reducing the chances of overlooking important services.

Organizing Maintenance Records

- Use a standardized format for recording information, including vehicle details, service history, and maintenance logs.

- Utilize digital folders or databases to categorize records by vehicle, date, and type of maintenance for easy retrieval.

- Regularly update and review the records to ensure accuracy and completeness, minimizing errors and discrepancies.

Conclusion

In conclusion, maintaining a fleet vehicle requires dedication and attention to detail. By following a comprehensive checklist and staying on top of routine inspections and maintenance tasks, you can keep your vehicles running smoothly and efficiently.

Commonly Asked Questions

How often should I check the fluid levels in fleet vehicles?

Fluid levels should be checked regularly, ideally during every scheduled maintenance check or at least once a month.

What digital tools are recommended for tracking maintenance records?

Popular choices include fleet management software and maintenance tracking apps that allow easy organization and access to records.